Status Quo of Conservation Tillage Agricultural Machinery Operation Monitoring Technology

-

摘要:

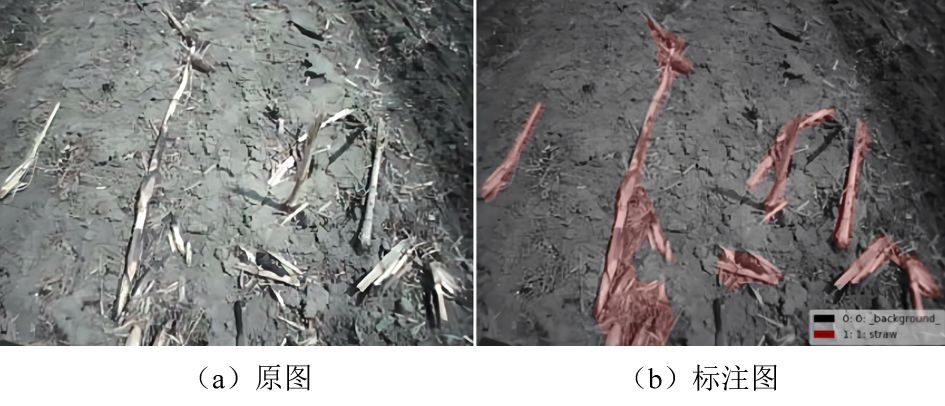

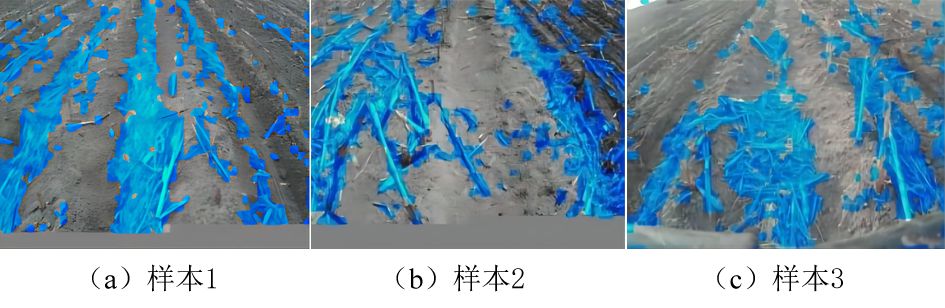

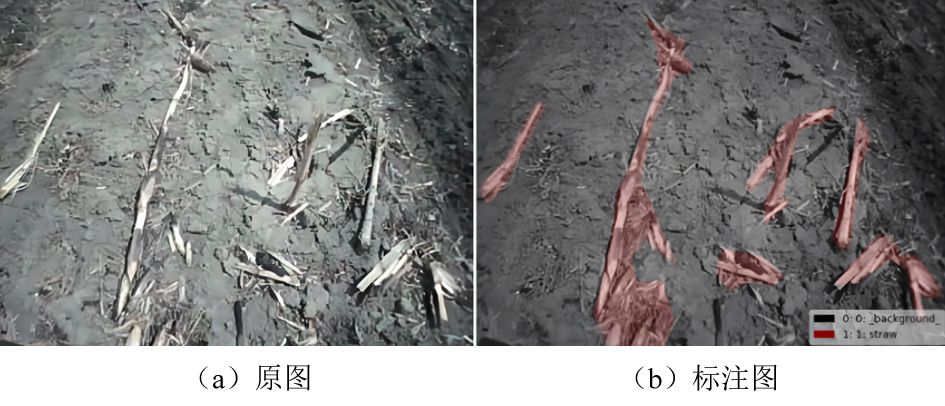

总结了秸秆覆盖率、免耕精量播种参数、机具作业面积等主要保护性耕作农机作业监测技术发展现状,并对典型保护性耕作监测设备进行了阐述和分析。在此基础上,归纳了现有保护性耕作农机作业监测技术面临的主要问题,并提出兼顾不同需求发展产品化、系列化、标准化的保护性耕作农机作业监测装备展望与建议,为解决制约保护性耕作快速发展的瓶颈问题提供参考。

Abstract:Development status of main conservation tillage agricultural machinery operation monitoring technologies such as straw coverage, no-tillage precision seeding parameters, and machine working area were summarized, and typical conservation tillage monitoring equipment was also analyzed.On this basis, combined with development requirements and application scenarios of conservation tillage, main problems faced by conservation tillage agricultural machinery operation monitoring technology were summarized, and development of productized, serialized and standardized conservation tillage agricultural machinery operation monitoring equipment that took into account different needs was proposed.To provide a reference for solving important bottleneck restricting development of conservation tillage, prospects and suggestions were put forward.

-

Keywords:

- operation monitoring /

- conservation tillage /

- straw coverage /

- no-tillage seeding

-

表 1 秸秆覆盖计算方法性能比较

Table 1. Performance comparison of straw mulching calculation methods

方法 平均误差/% 平均速度/(张·s−1) 人工拉绳法 8.48 72 图像智能分割算法 6.32 10 人工神经网络(以秸秆纹理特

征构建网络)5.00 8 FFT+SVM(提取秸秆高频信号,

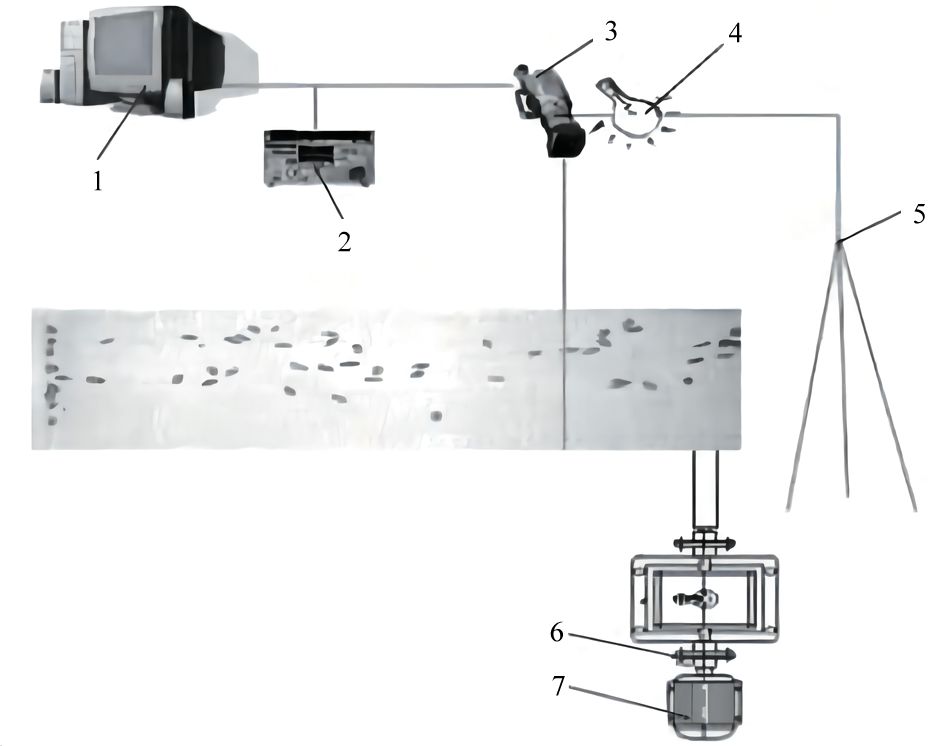

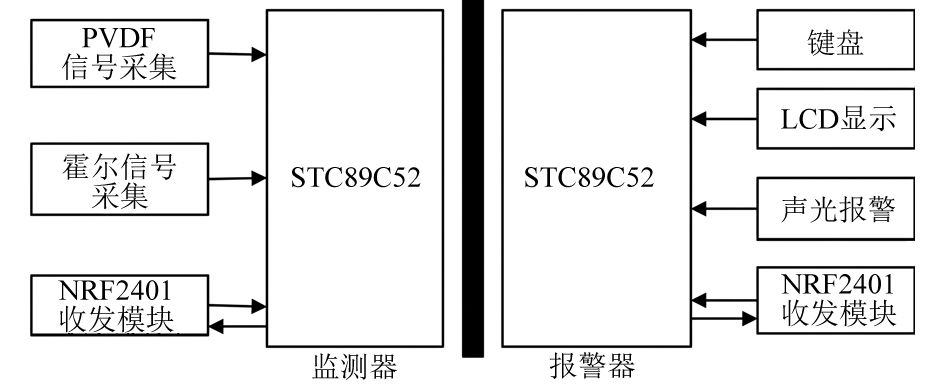

并进行高精度区分)4.55 0.05 表 2 常用电子式排种监测方法对比

Table 2. Comparison of commonly used electronic seed metering monitoring methods

监测方法 优点 缺点 适用场景 光电感应式 响应速度快、系统构建简单、成本低、使用方便、应用更为广泛 易受作业环境影响、无法监测破碎的种子、播种速度快或种子较小时,监测误差率较高 成本低、精度高,适于普通作业监测 机器视觉式 对检测种子的颗粒尺寸没有要求、监测精度高、可检测种子破碎率 对作业环境要求严格、成本较高限制推广应用、且劳动强度较大 成本高、精度高,适于育种检测、机具性能检测 电容感应式 抗干扰能力强、监测种子重播量、漏播量等参数精度较高 易受温度变化和寄生电容干扰,可靠性较低、稳定性不高、达不到实际应用要求 不适于实际应用 压电感应式 抗干扰能力强、简单可靠、有效地监测机具排种性能 改变种粒入土位置、增加了种管堵塞可能性 影响种子下落,不适于实际应用 表 3 常用机具作业面积监测方法对比

Table 3. Comparison of commonly used methods for monitoring working area of machine tools

监测方法 优点 缺点 适用场景 转速传感器 监测精度较高、成本低及安装采集数据方便 地轮打滑致使监测精度大大降低 成本低、精度高,适于普通作业监测 卫星导航系统 无需与地表接触,适应性强,较高监测精度 价格较高 有定位需要 -

[1] 王春雷,李洪文,何进,等.自动导航与测控技术在保护性耕作中的应用现状和展望[J].智慧农业(中英文),2020,2(4):41-55.WANG Chunlei,LI Hongwen,HE Jin,et al.State-of-the-art and prospect of automatic navigation and measurement techniques application in conservation tillage[J].Smart Agriculture,2020,2(4):41-55. [2] 王丽丽,徐岚俊,魏舒,等.基于Sauvola与Otsu算法的秸秆覆盖率图像检测方法[J].农业工程,2017,7(4):29-35. doi: 10.3969/j.issn.2095-1795.2017.04.009WANG Lili,XU Lanjun,WEI Shu,et al.Straw coverage detection method based on Sauvola and Otsu segmentation algorithm[J].Agricultural Engineering,2017,7(4):29-35. doi: 10.3969/j.issn.2095-1795.2017.04.009 [3] DAUGHTRY C S T,HUNT E R,MCMURTREY J E.Assessing crop residue cover using shortwave infrared reflectance[J].Remote Sensing of Environment,2004,90(1):126-134. doi: 10.1016/j.rse.2003.10.023 [4] 王昌昆.秸秆覆盖度遥感估算及其水分影响校正研究[D].北京: 中国科学院大学, 2013.WANG Changkun.Estimation of crop residue cover by remote sensing and correction of moisture effects on estimates[D].Beijing: University of Chinese Academy of Sciences, 2013. [5] 苏艳波,张东远,李洪文,等.基于自动取阈分割算法的秸秆覆盖率检测系统[J].农机化研究,2012,34(8):138-142. doi: 10.3969/j.issn.1003-188X.2012.08.034SU Yanbo,ZHANG Dongyuan,LI Hongwen,et al.Measuring system for residue cover rate based on automation threshold[J].Journal of Agricultural Mechanization Research,2012,34(8):138-142. doi: 10.3969/j.issn.1003-188X.2012.08.034 [6] 李佳,吕程序,苑严伟,等.快速傅里叶变换结合SVM算法识别地表玉米秸秆覆盖率[J].农业工程学报,2019,35(20):194-201. doi: 10.11975/j.issn.1002-6819.2019.20.024LI Jia,LV Chengxu,YUAN Yanwei,et al.Automatic recognition of corn straw coverage based on fast Fourier transform and SVM[J].Transactions of the Chinese Society of Agricultural Engineering,2019,35(20):194-201. doi: 10.11975/j.issn.1002-6819.2019.20.024 [7] 李洪文,李慧,何进,等.基于人工神经网络的田间秸秆覆盖率检测系统[J].农业机械学报,2009,40(6):58-62.LI Hongwen,LI Hui,HE Jin,et al.Measuring system for residue cover rate in field based on BP neural network[J].Transactions of the Chinese Society for Agricultural Machinery,2009,40(6):58-62. [8] 刘媛媛,王跃勇,于海业,等.基于多阈值图像分割算法的秸秆覆盖率检测[J].农业机械学报,2018,49(12):27- 35,55. doi: 10.6041/j.issn.1000-1298.2018.12.004LIU Yuanyuan,WANG Yueyong,YU Haiye,et al.Detection of straw coverage rate based on multi-threshold image segmentation algorithm[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(12):27- 35,55. doi: 10.6041/j.issn.1000-1298.2018.12.004 [9] 赵百通,张晓辉,孔庆勇,等.国内外精密播种机监控系统的现状和发展趋势[J].山东农机,2003(12):14-16.ZHAO Baitong,ZHANG Xiaohui,KONG Qingyong,et al.Starus adn developing trend of the domestic and foreign precision planter control system[J].Shandong Agricultural Machinery,2003(12):14-16. [10] 张景,纪超,陈金成,等.精量播种机排种质量电子监测技术研究现状[J].新疆农机化,2018(2):15-19. doi: 10.13620/j.cnki.issn1007-7782.2018.02.004ZHANG Jing,JI Chao,CHEN Jincheng,et al.Research status of electrical seeding quality monitoring technology for precision seeder[J].Xinjiang Agricultural Mechanization,2018(2):15-19. doi: 10.13620/j.cnki.issn1007-7782.2018.02.004 [11] 杨丽,史嵩,崔涛,等.气吸与机械辅助附种结合式玉米精量排种器[J].农业机械学报,2012,43(S1):48-53.YANG Li,SHI Song,CUI Tao,et al.Air-suction corn precision metering device with mechanical supporting plate to assist carrying seed[J].Transactions of the Chinese Society for Agricultural Machinery,2012,43(S1):48-53. [12] 吴艳艳,朱瑞祥,常芳.播种机播种质量检测预警系统[J].农机化研究,2013(5):196-199. doi: 10.3969/j.issn.1003-188X.2013.05.049WU Yanyan,ZHU Ruixiang,CHANG Fang.Monitoring and warning system on sowing quality for seeder[J].Journal of Agricultural Mechanization Research,2013(5):196-199. doi: 10.3969/j.issn.1003-188X.2013.05.049 [13] 刘春旭,赵德春,单爱军.红外反射式播种机电子监测装置的设计[J].农机化研究,2010,32(6):117-120. doi: 10.3969/j.issn.1003-188X.2010.06.031LIU Chunxu,ZHAO Dechun,SHAN Aijun.Design of infrared reflective electro-monitor for seeding machine.[J].Journal of Agricultural Mechanization Research,2010,32(6):117-120. doi: 10.3969/j.issn.1003-188X.2010.06.031 [14] AKDEMIR B,KAYISOGLU B,BENET B.Development of an image analysis system for sowing machine laboratory tests[J].Agricultural Mechanization in Asia Africa and Latin America,2014,45(3):49-55. [15] 周利明.基于电容法的棉花产量和播种量检测技术研究[D].北京: 中国农业大学, 2014.ZHOU Liming.Research on detection of yield and seeding rate of cotton based on capacitive method [D].Beijing: China Agricultural University, 2014. [16] 黄东岩,贾洪雷,祁悦,等.基于聚偏二氟乙烯压电薄膜的播种机排种监测系统[J].农业工程学报,2013,29(23):15-22. doi: 10.3969/j.issn.1002-6819.2013.23.003HUANG Dongyan,JIA Honglei,QI Yue,et al.Seeding monitor system for planter based on polyvinylidence fluoride piezoelectric film[J].Transactions of the Chinese Society of Agricultural Engineering,2013,29(23):15-22. doi: 10.3969/j.issn.1002-6819.2013.23.003 [17] 黄东岩,朱龙图,贾洪雷,等.基于压电薄膜的免耕播种机播种深度控制系统[J].农业机械学报,2015,46(4):1-8. doi: 10.6041/j.issn.1000-1298.2015.04.001HUANG Dongyan,ZHU Longtu,JIA Honglei,et al.Automatic control system of seeding pepth based on piezoelectric film for no-till plante[J].Transactions of the Chinese Society for Agricultural Machinery,2015,46(4):1-8. doi: 10.6041/j.issn.1000-1298.2015.04.001 [18] 周晓飞.汽车传感器维修百日通[M].北京: 化学工业出版社, 2019. [19] 吴建平.传感器原理及其应用[M].北京: 机械工业出版社, 2016. [20] 董燕.精准定位变率施肥播种免耕机的研究[D].青岛: 山东科技大学, 2010.DONG Yan.Precise variability fertilization no-till seeder[D].QingDao: Shandong University of Science and Technology, 2010. [21] 孙永佳,沈景新,窦青青,等.基于Cortex-M3的免耕播种机监控系统设计与试验[J].农业机械学报,2018,49(8):50-58. doi: 10.6041/j.issn.1000-1298.2018.08.006SUN Yongjia,SHEN Jingxin,DOU Qingqing,et al.Design and test of monitoring system of no-tillage planter based on Cortex-M3 processor[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(8):50-58. doi: 10.6041/j.issn.1000-1298.2018.08.006 [22] 黄东岩,朱龙图,贾洪雷,等.基于GPS和GPRS的远程玉米排种质量监测系统[J].农业工程学报,2016,32(6):162-168. doi: 10.11975/j.issn.1002-6819.2016.06.022HUANG Dongyan,ZHU Longtu,JIA Honglei,et al.Remote monitoring system for corn seeding quality based on GPS and GPRS[J].Transactions of the Chinese Society of Agricultural Engineering,2016,32(6):162-168. doi: 10.11975/j.issn.1002-6819.2016.06.022 [23] 隋铭明,沈飞,徐爱国,等.基于北斗卫星导航的秸秆机械化还田作业管理系统[J].农业机械学报,2016,47(1):23-28. doi: 10.6041/j.issn.1000-1298.2016.01.004SUI Mingming,SHEN Fei,XU Aiguo,et al.Management system for mechanized straw returning based on BDS[J].Transactions of the Chinese Society of Agricultural Machinery,2016,47(1):23-28. doi: 10.6041/j.issn.1000-1298.2016.01.004 [24] 李洪文.我国保护性耕作发展与建议[N].中国农机化导报, 2019-09-02(2). -

下载:

下载:

京公网安备 11010502037498号

京公网安备 11010502037498号