Flow Characteristics Simulation of Biodiesel/N-amyl Alcohol Mixed Fuel Nozzles

-

摘要:

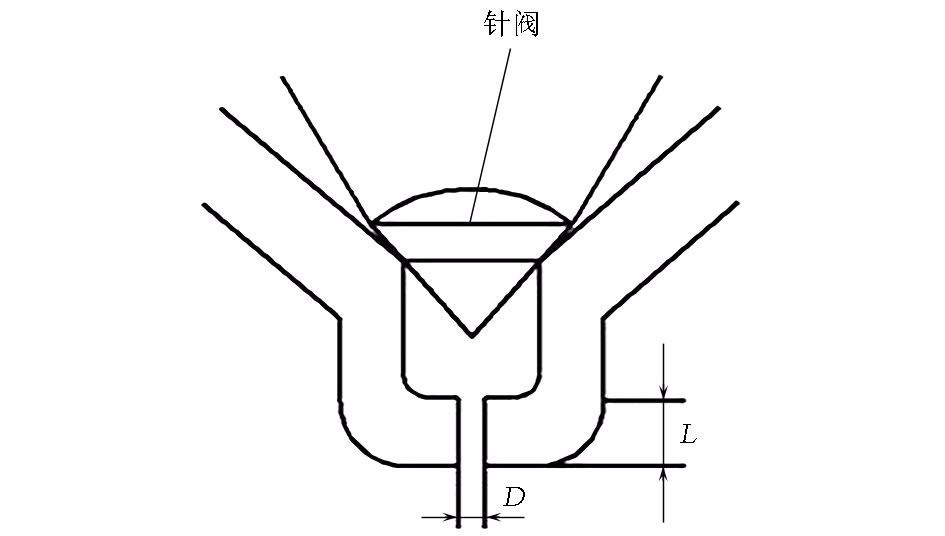

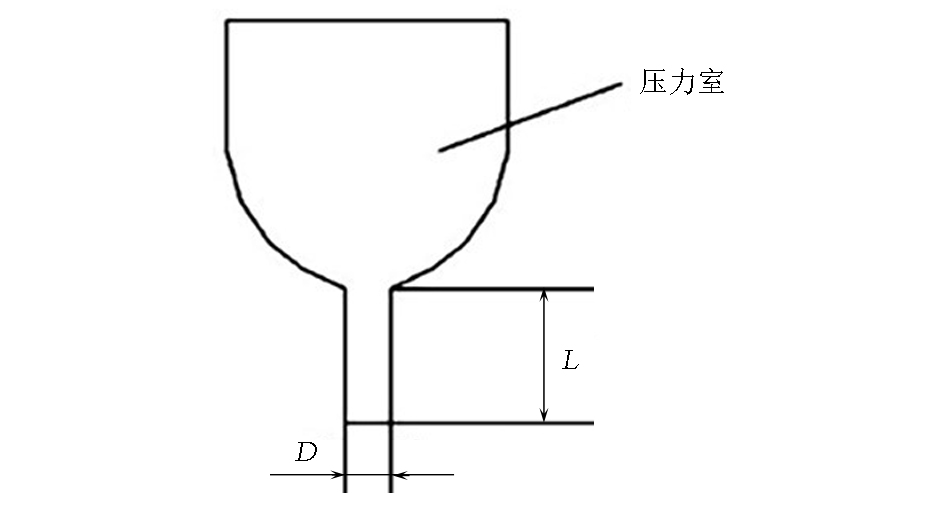

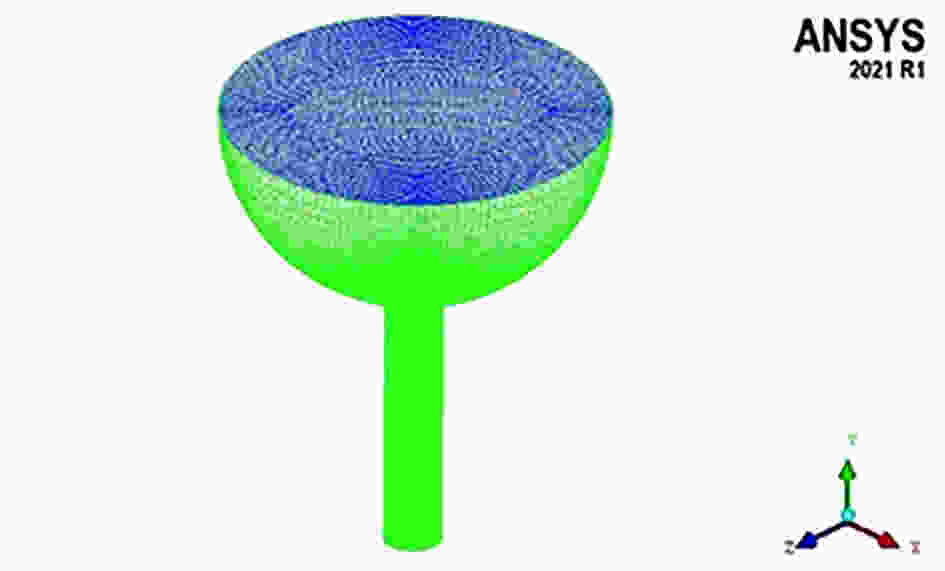

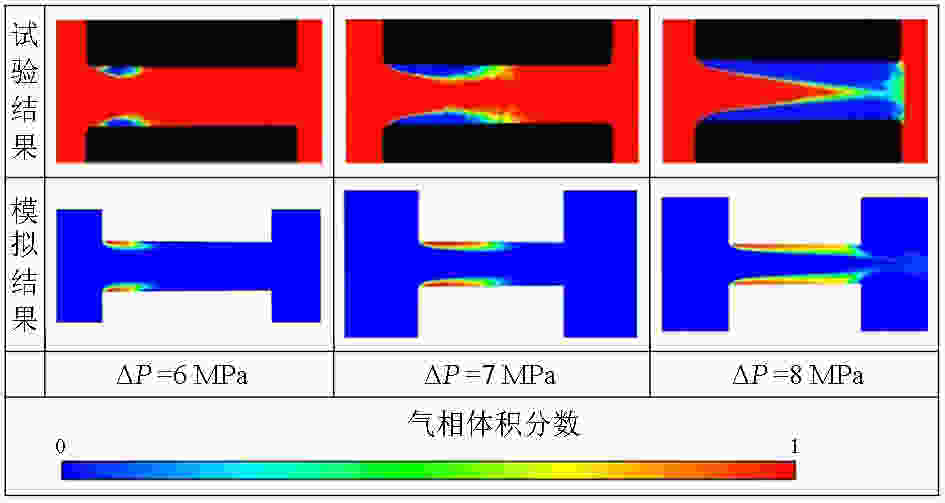

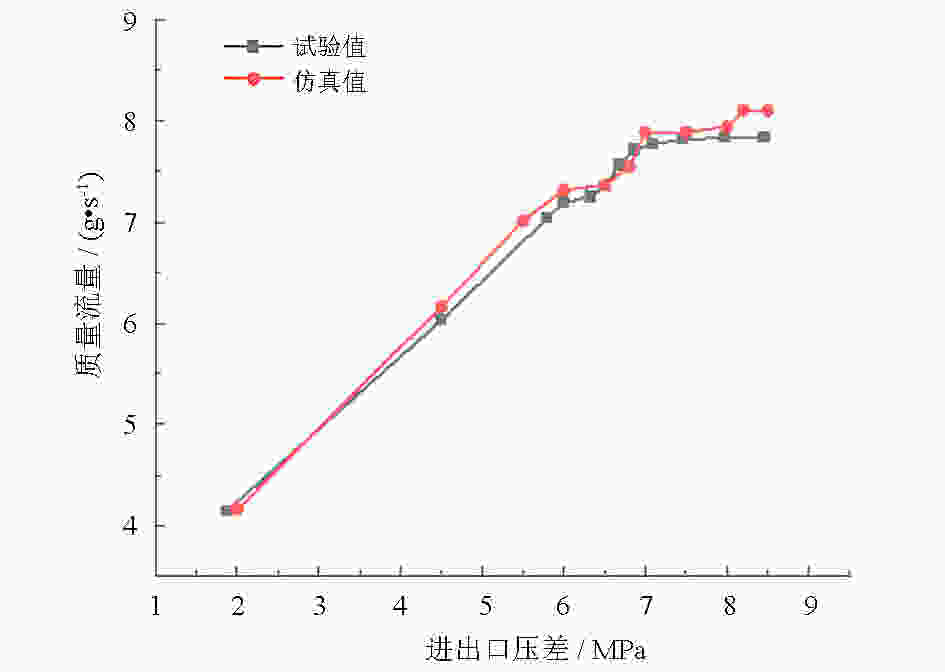

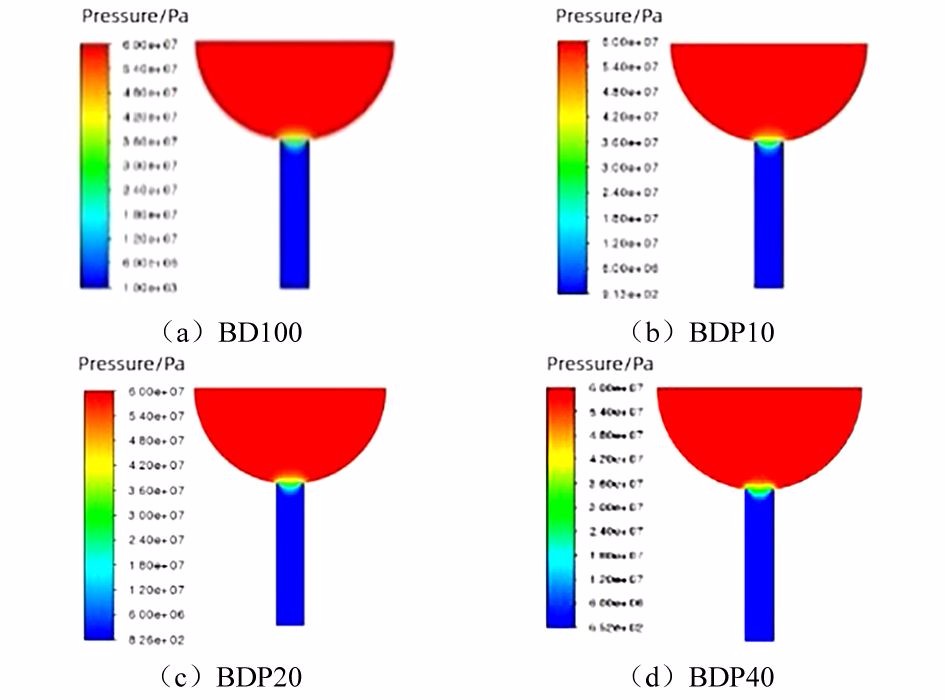

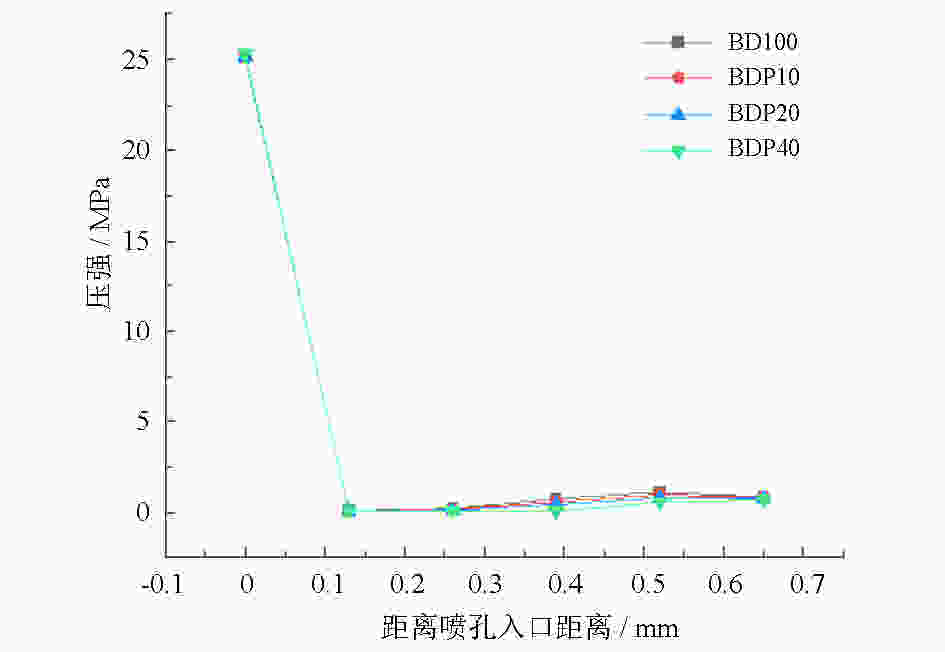

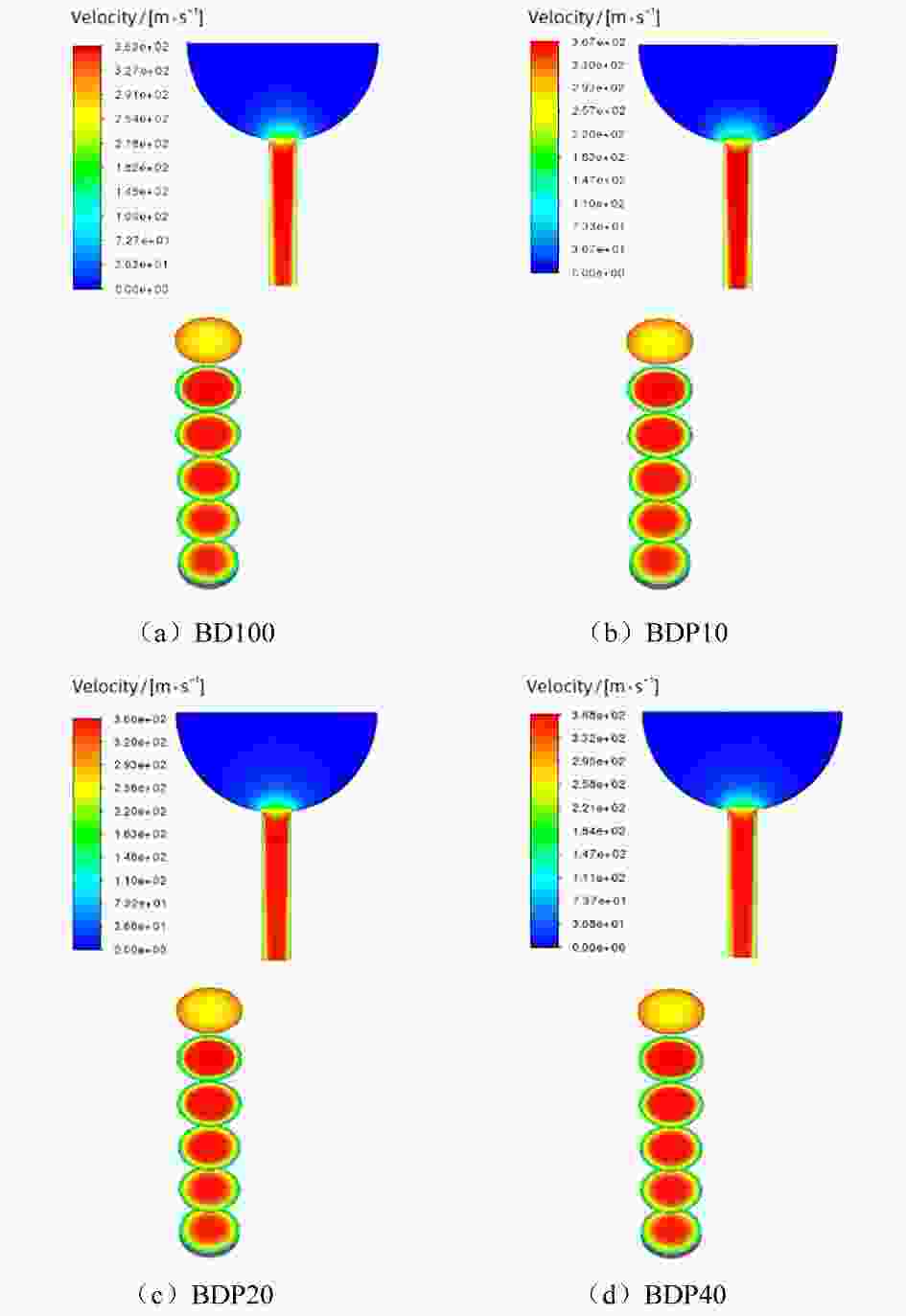

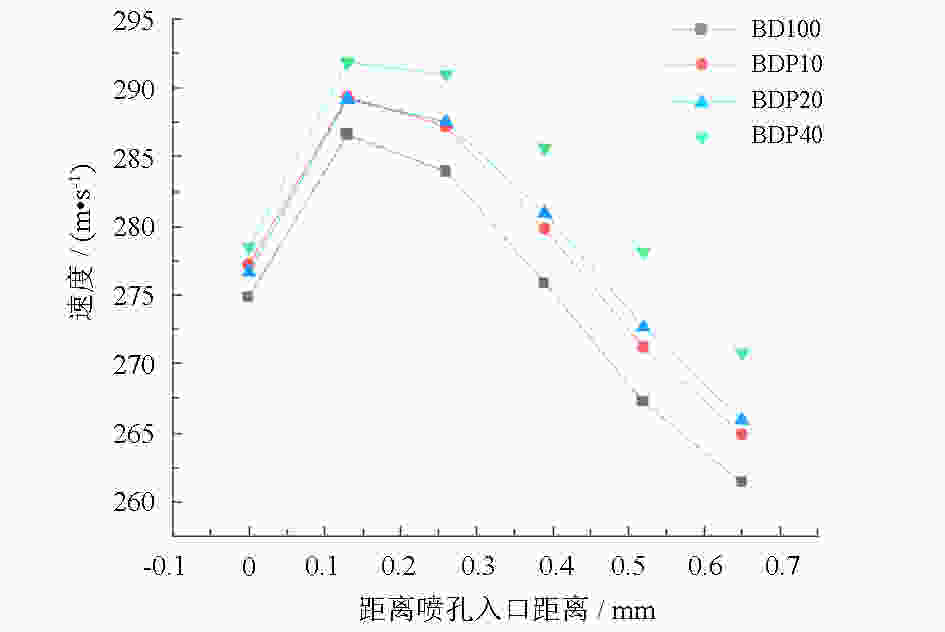

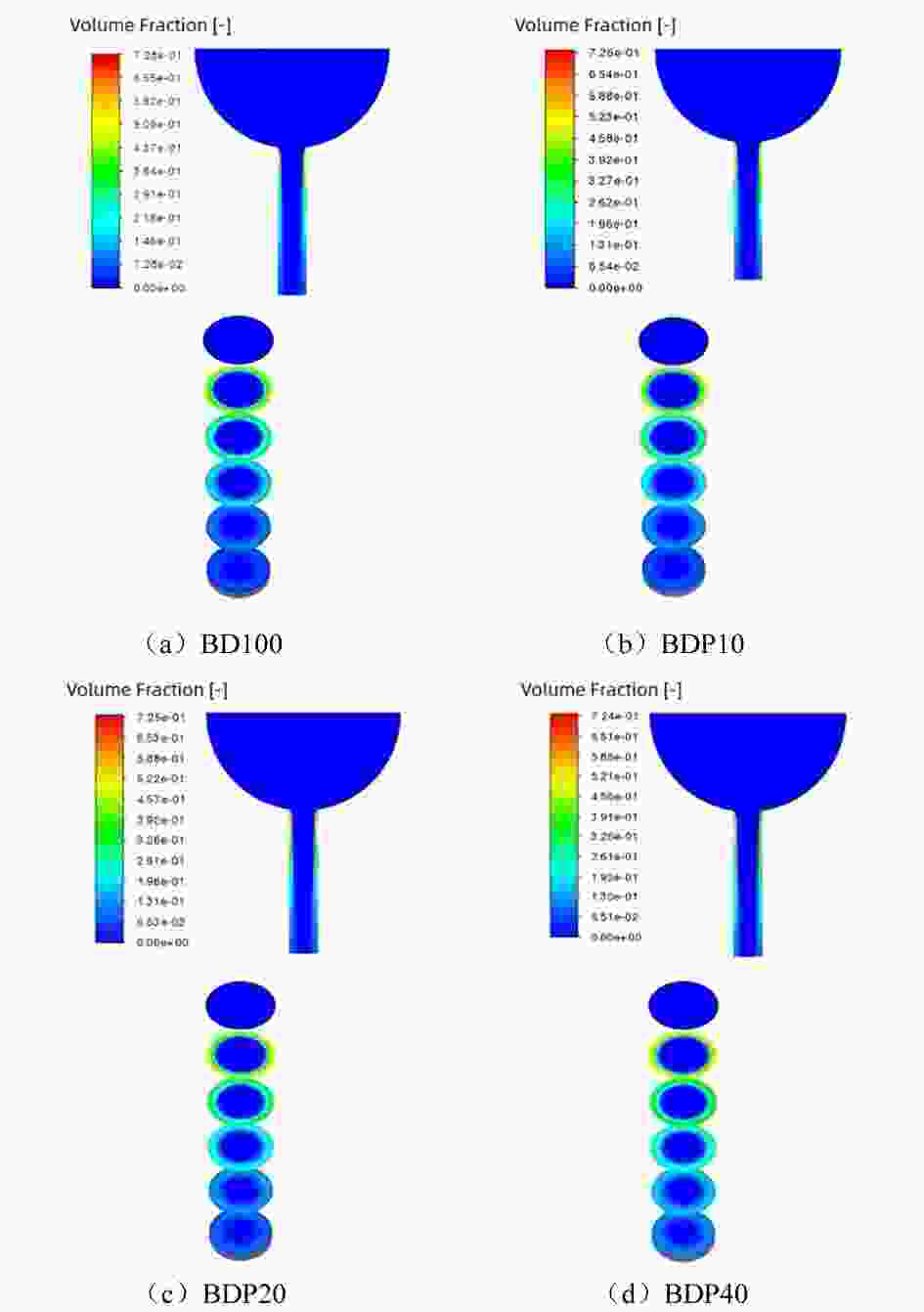

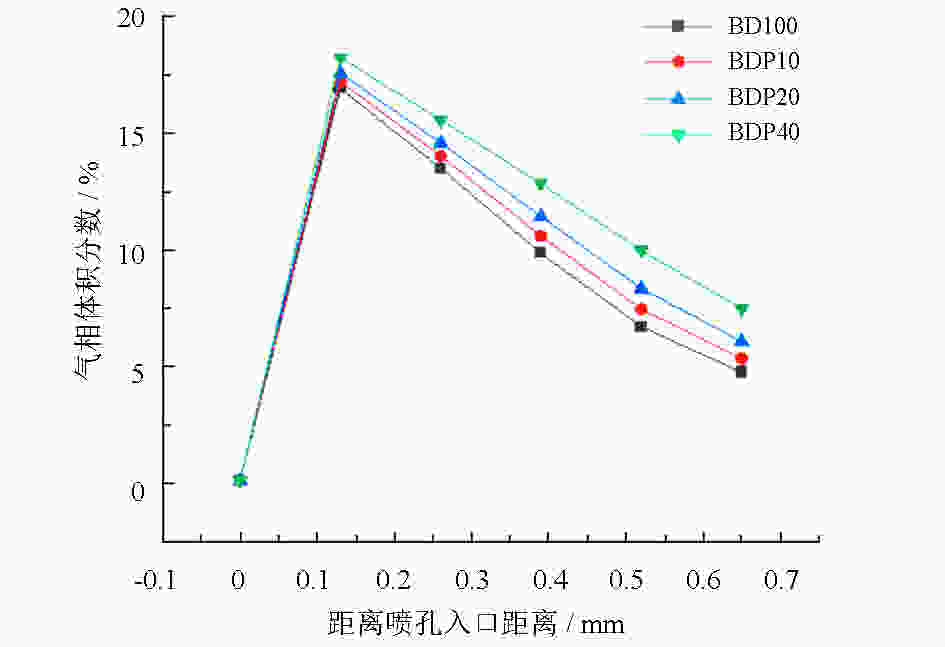

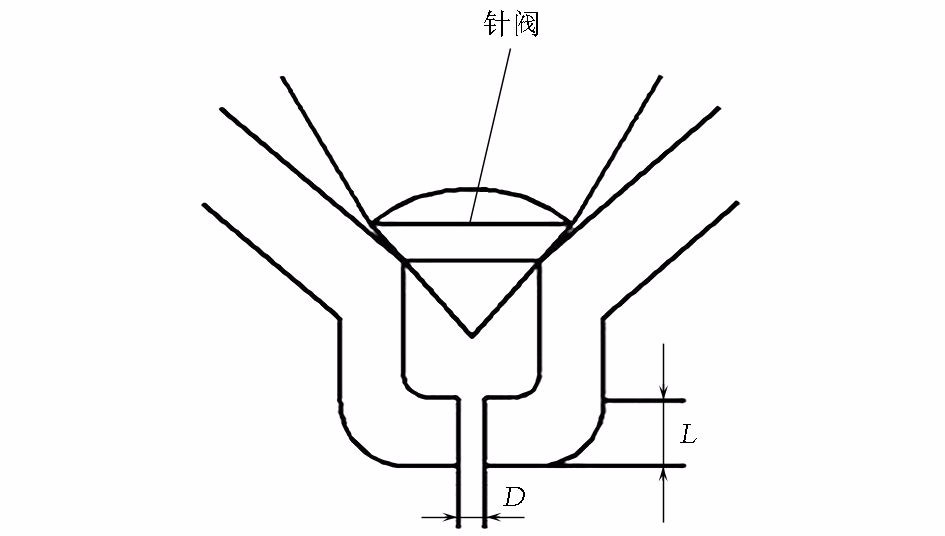

为探究混合燃油理化性质差异对柴油机喷嘴内流动特性的影响,以4种不同掺混比的生物柴油/正戊醇为研究对象,采用混合多相流模型,对柴油机喷嘴内的流动情况进行数值模拟分析。结果表明:4种燃油的压力、速度和空化分布特性基本一致;随着正戊醇掺混比例的增加,混合燃油速度和气相体积分数大小在喷孔同一截面处均表现为增加趋势,向生物柴油中掺混一定比例的正戊醇,可以显著降低生物柴油的密度、黏度和表面张力,提高燃油在喷孔内的流动性、促进燃油的空化生成,提升燃油的雾化效果。

Abstract:In order to explore influence of physicochemical properties of mixed fuel on flow characteristics in nozzles of diesel engine, mixed multiphase flow model was used to simulate flow in nozzles of diesel engine with four different mixing ratios of biodiesel/n-amyl alcohol.Results showed that pressure, velocity and cavitation distribution characteristics of four fuels were basically the same.With increase of mixing ratio of n-amyl alcohol, speed of mixed fuel gas phase volume fraction in spray hole size the same cross-section were characterized by increasing trend, biodiesel mixed in certain proportion was n-amyl alcohol and biodiesel could significantly reduce density, viscosity and surface tension, improve fuel in liquidity, promote cavitation generation of fuel, and improve fuel atomization effect.

-

Keywords:

- biodiesel oil /

- n-amyl alcohol /

- mixed fuel /

- numerical simulation

-

表 1 燃油物性参数(20 °C)

Table 1. Physical parameters of fuel (20 °C)

物性参数 密度/

(kg·m−3)黏度/

(mPa·s)表面张力/

(10−3N·m−1)饱和蒸

汽压/kPa燃油种类 BD100 871.4 6.24 30.3 1.000 表 2 数值模拟边界条件

Table 2. Numerical simulation of boundary conditions

边界条件 数值 喷射压力/MPa 60 环境背压/MPa 1 环境温度/K 293.15 -

[1] 王海滨.基于国3柴油机的生物柴油混合燃料的性能与排放研究[D].上海: 上海交通大学, 2007.WANG Haibin.Characteristics of performances and emissions of biodiesel blends based on Euro-III diesel engine[D].Shanghai: Shanghai Jiao Tong University, 2007. [2] 郑尊清,钟小凡,刘海峰,等.生物柴油/DMF混合燃料对柴油机低温燃烧的影响[J].燃烧科学与技术,2017,23(2):104-110.ZHENG Zunqing,ZHONG Xiaofan,LIU Haifeng,et al.Effect of biodiesel/DMF blended fuel on low temperature combustion in a diesel engine[J].Journal of Combustion Science and Technology,2017,23(2):104-110. [3] 戴广林,赵洋,王巍,等.含水乙醇/生物柴油燃烧与排放分析[J].常熟理工学院学报,2020,34(5):115-118. doi: 10.3969/j.issn.1008-2794.2020.05.025DAI Guanglin,ZHAO Yang,WANG Wei,et al.Effect of water content on biodiesel/ethanol combustion and emissions[J].Journal of Changshu Institute of Technology (Natural Sciences),2020,34(5): 115 -118. doi: 10.3969/j.issn.1008-2794.2020.05.025 [4] TOSUN E,YILMAZ A C,OZCANLI M,et al.Determination of effects of various alcohol additions into peanut methyl ester on performance and emission characteristics of a compression ignition engine[J].Fuel,2014,126:38-43. doi: 10.1016/j.fuel.2014.02.037 [5] BABU D,ANAND R.Effect of biodiesel-diesel-n-pentanol and biodiesel-diesel-n-hexanol blends on diesel engine emission and combustion characteristics[J].Energy,2017,133:761-776. doi: 10.1016/j.energy.2017.05.103 [6] CAMPOS-FERNANDEZ J,ARNAL J M,GOMEZ J,et al.Performance tests of a diesel engine fueled with pentanol/diesel fuel blends[J].Fuel,2013,107:866-872. doi: 10.1016/j.fuel.2013.01.066 [7] ASHOK B,JEEVANANTHAM A K,NANTHAGOPAL K,et al.An experimental analysis on the effect of n-pentanol-Calophyllum Inophyllum Biodiesel binary blends in CI engine characteristcis[J].Energy,2019,173:290-305. doi: 10.1016/j.energy.2019.02.092 [8] 李莉,王建昕,王志,等.柴油机燃用新型戊醇混合燃料的燃烧和排放特性[J].内燃机学报,2015,33(2):97-103.LI Li,WANG Jianxin,WANG Zhi,et al.Combustion and emissions of diesel engine fueled with pentanol blended fuel[J].Transactions of CSICE,2015,33(2):97-103. [9] 马寅杰.定容弹内正戊醇/柴油/生物柴油混合燃料喷雾燃烧及联合反应机理研究[D].武汉: 华中科技大学, 2017.MA Yinjie.Investigation on n-pentanol/diesel/biodiesel blended fuel spray combustion and combined combustion mechanism in constant volume combustion chamber[D].Wuhan: Huazhong University of Science & Technology, 2017. [10] PAYRI F,BERMÚDEZ V,PAYRI R,et al.The influence of cavitation on the internal flow and the spray characteristics in diesel injection nozzles[J].Fuel,2003,83(4):419-431. [11] 汪翔,苏万华.空化过程对柴油喷嘴内流特性的影响[J].内燃机学报,2007,25(6):481-487. doi: 10.3321/j.issn:1000-0909.2007.06.001WANG Xiang,SU Wanhua.The influence of cavitation processes on the internal flow characteristics of diesel injection nozzles[J].Transactions of CSICE,2007,25(6):481-487. doi: 10.3321/j.issn:1000-0909.2007.06.001 [12] SOM S,LONGMAN D E,RAMÍREZ A I,et al.A comparison of injector flow and spray characteristics of biodiesel with petrodiesel[J].Fuel,2010,89(12): 4014 - 4024. doi: 10.1016/j.fuel.2010.05.004 [13] 李莉.基于生物柴油和戊醇的燃料设计及其燃烧和排放特性研究[D].北京: 清华大学, 2016.LI Li.Research on the fuel design and combustion and emission characteristics of biodiesel-pentanol-diesel[D].Beijing: Tsinghua University, 2016. [14] 邵壮,何志霞,钟汶君,等.柴油与生物柴油不同长径比喷嘴内空穴流动的试验[J].内燃机学报,2014,32(4):322-327. doi: 10.16236/j.cnki.nrjxb.2014.04.006SHAO Zhuang,HE Zhixia,ZHONG Wenjun,et al.Visualization experiment on cavitating flow of different length diameter ratios using diesel and biodiesel in diesel engine nozzles[J].Transactions of CSICE,2014,32(4):322-327. doi: 10.16236/j.cnki.nrjxb.2014.04.006 [15] 胡惟孝, 杨忠愚.有机化合物制备手册: 第1卷[M].天津: 天津科技翻译出版公司, 1995. [16] 杜家益,李俊,张登攀,等.甲醇−调合生物柴油燃烧及排放微粒粒径分布特性试验[J].农业工程学报,2016,32(12):75-80. doi: 10.11975/j.issn.1002-6819.2016.12.011DU Jiayi,LI Jun,ZHANG Pandeng,et al.Experiments on combustion and emission particulate size distribution characteristics of diesel engine fueled with methanol-blending biosiesel fuel[J].Transactions of the Chinese Society of Agricultural Engineering,2016,32(12): 75 -80. doi: 10.11975/j.issn.1002-6819.2016.12.011 [17] 耿莉敏,王城,魏有涛,等.生物质混合燃料在柴油机喷嘴内流动特性模拟[J].农业工程学报,2017,33(21):70-77. doi: 10.11975/j.issn.1002-6819.2017.21.008GENG Limin,WANG Cheng,WEI Youtao,et al.Simulation on internal flow characteristics of nozzle for diesel engine fueled with biomass blend fuel[J].Transactions of the Chinese Society of Agricultural Engineering,2017,33(21):70-77. doi: 10.11975/j.issn.1002-6819.2017.21.008 [18] WINKLHOFER E, KULL E, KELZ E, et al.Comprehensive hydraulic and flow field documentation in model throttle experiments under cavitation conditions[C]//Proceedings of the ILASS-Europe conference, Zurich, 2001: 574-579. -

下载:

下载:

京公网安备 11010502037498号

京公网安备 11010502037498号