Experimental Study on Potting Characteristics of Rice Seedling in Hole Tray

-

摘要:

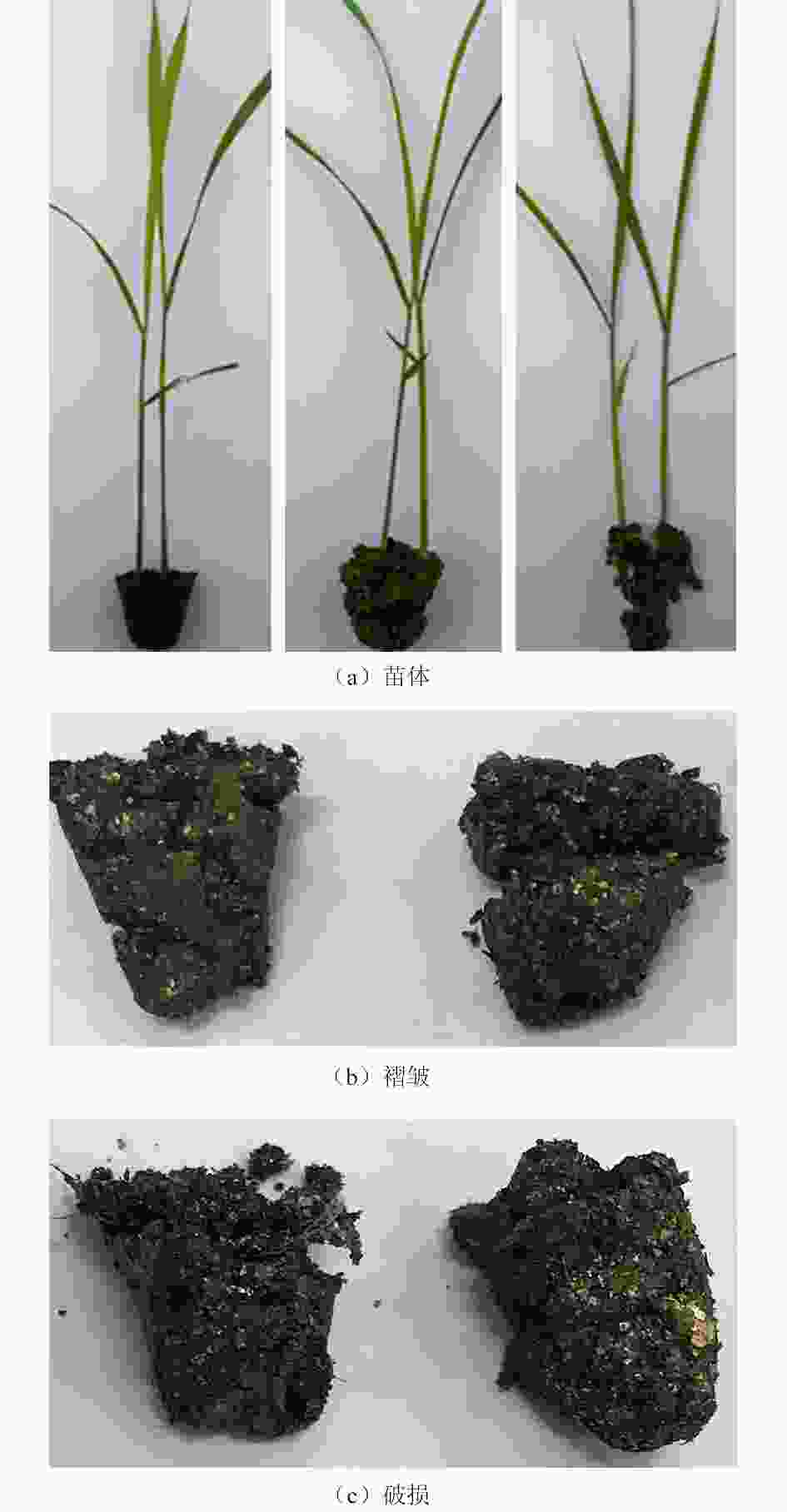

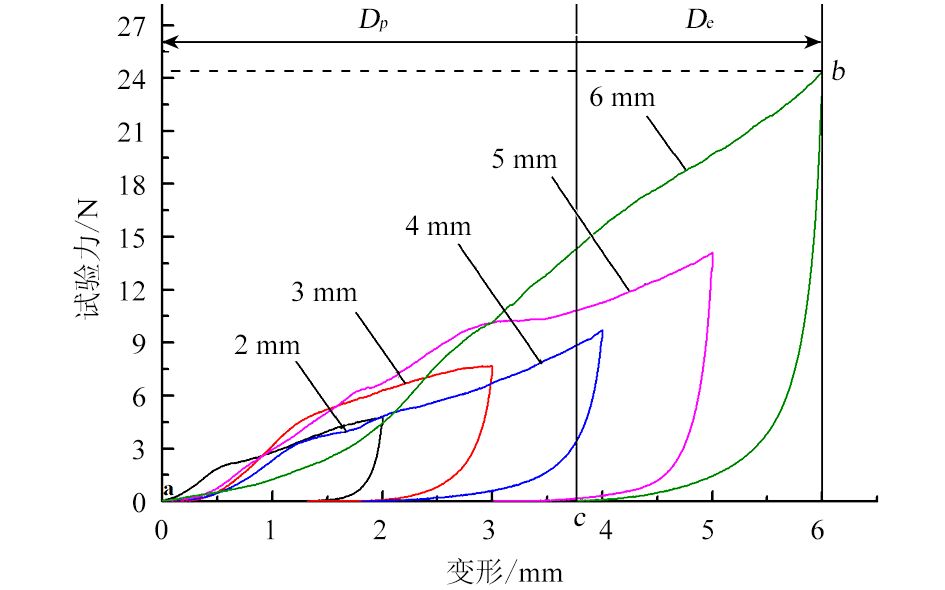

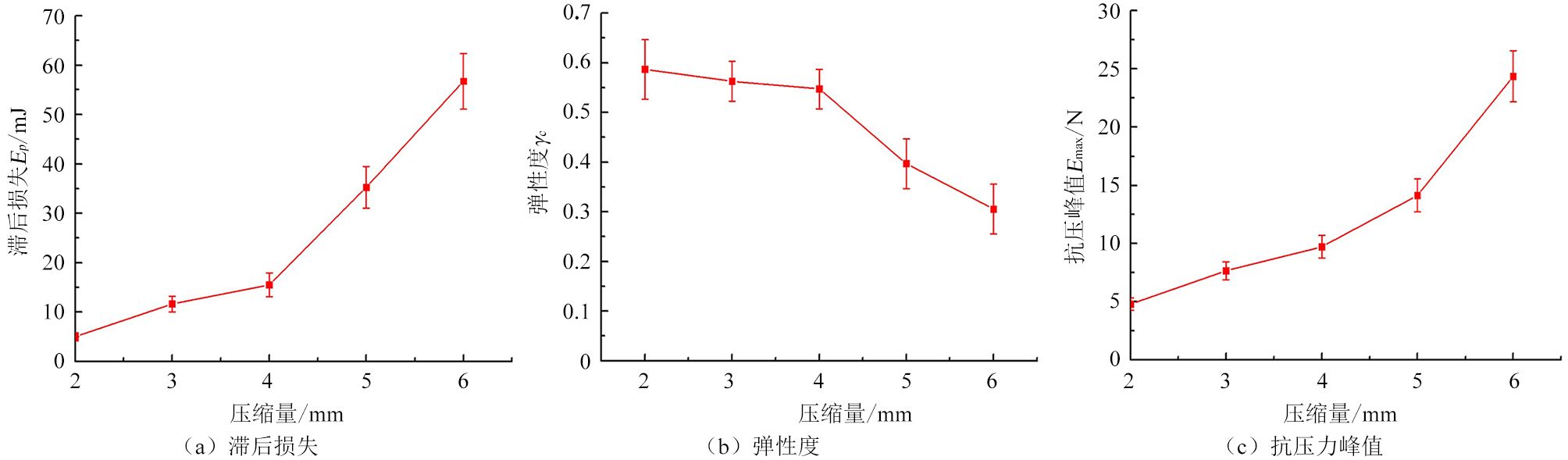

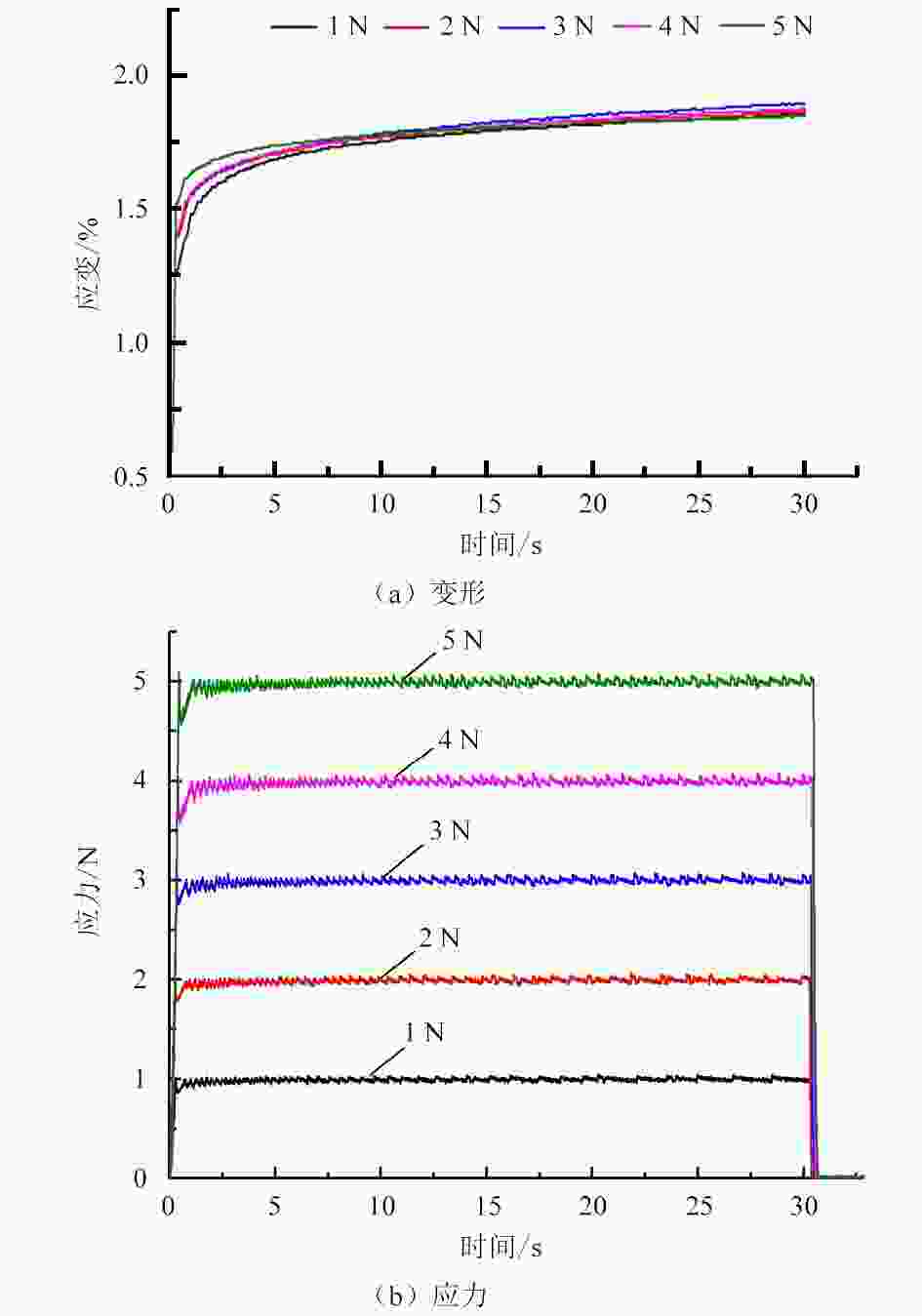

以培杂泰丰杂交稻种为试验对象,在立体育秧温室培育穴盘秧苗。试验时苗龄28 d,钵体含水率35.76%~54.08%,仪器为TA-XT2i型质地分析仪。对穴盘苗钵体进行平板压缩、加卸载循环和蠕变试验研究,发现平板压缩变形约3.15 mm,抗压力随变形的变化趋势差异明显,压缩约4 mm ,抗压力出现峰值上升变化陡点。当加载力为1、2、3、4和5 N,秧苗钵体平均蠕变量0.0055、0.0055、0.0056、0.0057和0.0059 mm。试验结果表明,钵体抗压力与变形呈非线性变动;平板压缩过程,钵体无明显屈服破坏点;苗钵体面对外界加卸载时表现较强塑变能力。选用Burgers模型能有效表征穴盘苗钵体压缩蠕变特性。分析多种稻种穴盘苗力学特性,结果发现不同穴盘苗钵体抗压力与变形关系遵循非线性曲线。该研究可为水稻移栽机设计优化提供理论参考。

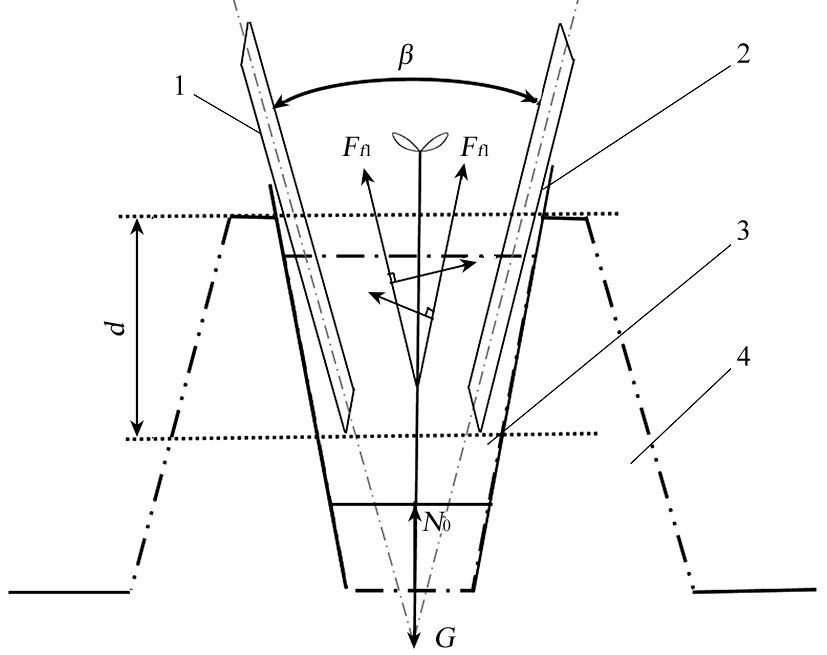

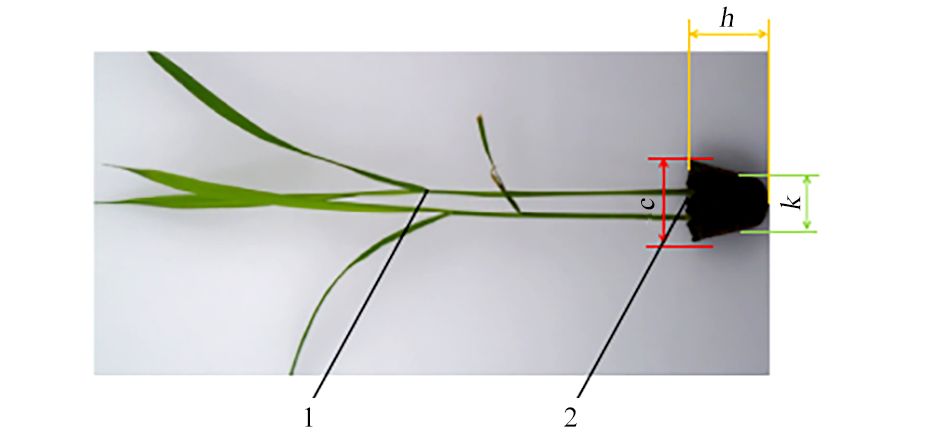

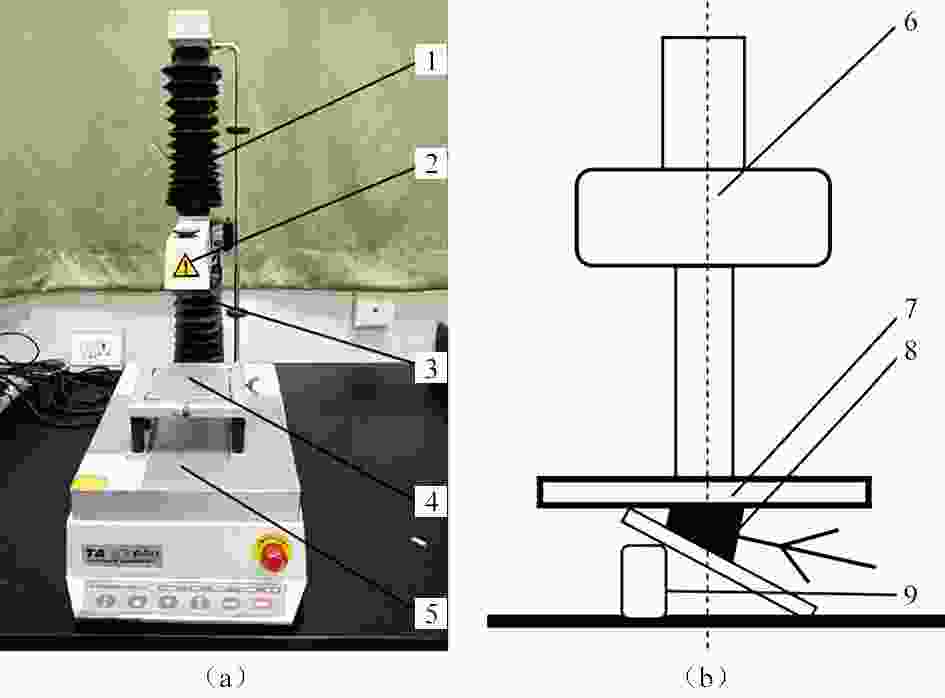

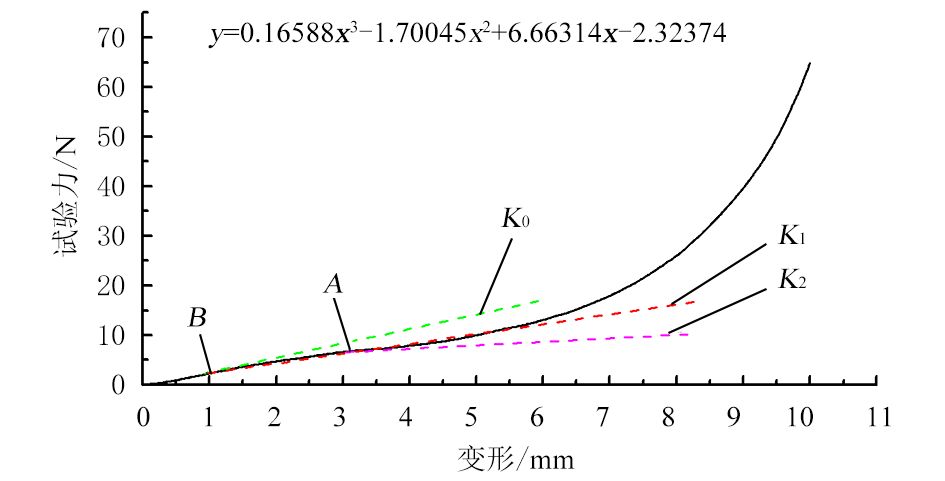

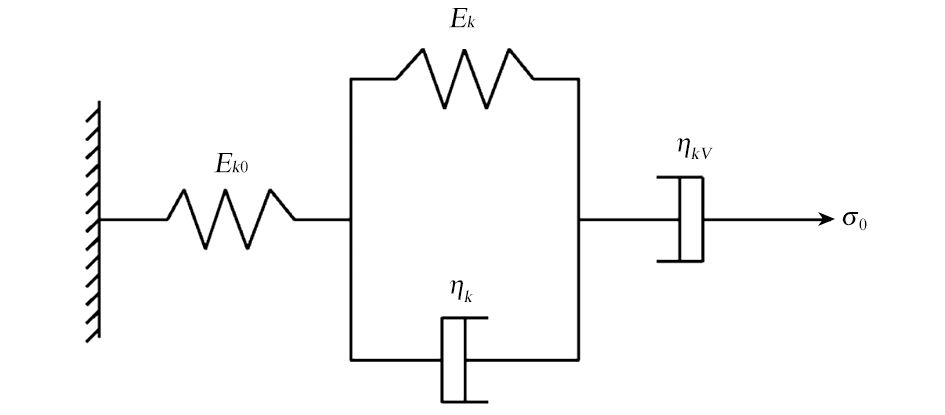

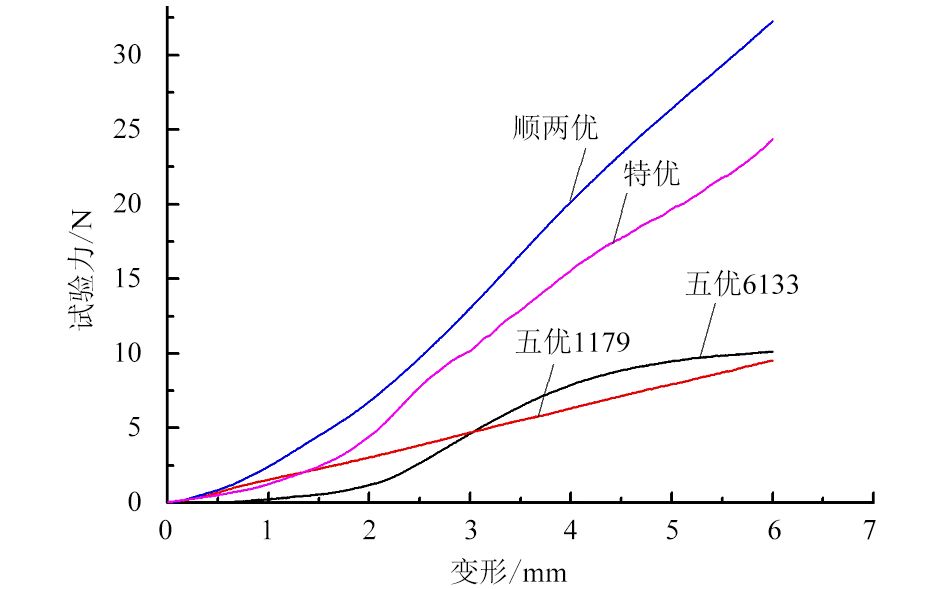

Abstract:Using Peiza Taifeng hybrid rice as experimental object, hole tray seedlings were cultivated in a three-dimensional seedling greenhouse.During experiment, seedling age was 28 d, moisture content of bowl was 35.76% to 54.08%.Instrument used was the TA-XT2i texture analyzer.A study was conducted on plate compression, loading and unloading cycles, and creep tests of hole tray seedling bowl.It was found that compression deformation of plate was about 3.15 mm, and there was a significant difference in trend of pressure resistance with deformation; compression was about 4 mm, and peak value of pressure resistance increased sharply.When loading force was 1, 2, 3, 4, and 5 N, average creep of seedling bowl was 0.0055, 0.0055, 0.0056, 0.0057, and 0.0059 mm.Experimental results showed that pressure resistance and deformation of bowl body exhibited nonlinear changes; during compression process of flat plate, there was no obvious yield failure point on bowl body; seedling bowl exhibited strong plastic deformation ability when facing external loading and unloading.Burgers model ccould effectively characterize compressive creep characteristics of tray seedling bowl.Mechanical properties of various rice seed hole tray seedlings were analyzed.It was found that relationship between pressure resistance and deformation of different hole tray seedling bowl bodies followed a nonlinear curve.This study could provide theoretical reference for design optimization of rice transplanters.

-

Keywords:

- rice /

- potting seedling /

- mechanical properties /

- compression /

- loading and unloading cycles /

- creep

-

表 1 不同生长期穴盘秧苗苗高

Table 1. Seedling height of hole tray seedlings at different growth periods

单位:cm 天数 钵苗序号 平均值 1 2 3 4 5 第8天 8.9 7.6 9.2 8.5 8.1 8.5 第12天 12.8 13.1 12.5 11.7 11.2 12.3 第16天 16.5 16.2 17.2 16.5 17.2 16.7 第20天 17.8 16.9 18.5 16.7 17.9 17.6 表 2 出苗率、成苗率和小苗率试验结果

Table 2. Seedling emergence,seedling success and seedling rate test results

单位:% 序号 出苗率 成苗率 小苗率 第1盘 82.32 79.56 3.08 第2盘 82.36 79.45 4.12 第3盘 82.28 79.36 5.15 表 3 秧苗素质试验结果

Table 3. Results of seedling quality test

序号 叶龄/叶 苗高/cm 苗茎宽/cm 根干

质量/g茎叶干

质量/g壮苗指数 第1盘 2.94 16.72 1.42 11.5 16.3 0.14 第2盘 2.96 17.86 1.54 11.7 17.1 0.15 第3盘 2.68 18.15 1.52 10.4 12.7 0.15 表 4 苗钵含水率测定结果

Table 4. Determination of water content of seedling pots

苗盘 试验序号 钵体湿质量/g 钵体干质量/g 含水率/% 第1盘 1 2.6 1.4 46.1 2 3.2 2.1 34.4 3 2.8 1.6 42.9 4 2.9 1.7 41.3 5 2.9 1.5 48.3 平均值 2.88 1.66 42.60 第2盘 1 2.2 1.6 27.3 2 2.7 1.8 33.3 3 2.9 1.9 34.5 4 3.1 1.7 45.2 5 2.6 1.6 38.5 平均值 2.70 1.72 35.76 第3盘 1 3.3 1.5 54.5 2 3.4 1.6 52.9 3 3.1 1.4 54.8 4 3.2 1.5 53.1 5 2.9 1.3 55.1 平均值 3.18 1.46 54.08 表 5 不同压力载荷下钵体蠕变参数

Table 5. Creep parameters of mantle under different pressure loads

加载力/N E1/(N·mm−1) E2/(N·mm−1) η1/(N·mm−1) η2/(N·mm−1) Trel/s R2 1 3.315 0.743 122.5 0.487 0.362 0.9955 2 2.564 1.209 255.8 0.183 0.221 0.9939 3 1.824 1.795 377.7 0.119 0.214 0.9974 4 1.877 2.397 456.7 0.090 0.215 0.9974 5 1.843 2.923 935.8 0.067 0.195 0.9931 -

[1] 贾旋,宋建农,王继承,等.秧龄和基土比对机插大钵体毯状苗晚稻群体质量和产量的影响[J].农业工程学报,2022,38(12): 1 - 11 . doi: 10.11975/j.issn.1002-6819.2022.12.001JIA Xuan,SONG Jiannong,WANG Jicheng,et al.Effects of seedling age and substrate soil ratio on the population quality and yield of late rice of machine-transplanted large-pot carpet seedlings[J].Transactions of the Chinese Society of Agricultural Engineering,2022,38(12): 1 - 11 . doi: 10.11975/j.issn.1002-6819.2022.12.001 [2] 李泽华,马旭,陈林涛,等.育秧播种密度与取秧面积耦合对杂交稻机插质量和产量的影响[J].农业工程学报,2019,35(24): 20 - 30 . doi: 10.11975/j.issn.1002-6819.2019.24.003LI Zehua,MA Xu,CHEN Lintao,et al.Effects of coupling of nursing seedling densities and seedling fetching area on transplanting quality and yield of hybrid rice[J].Transactions of the Chinese Society of Agricultural Engineering,2019,35(24): 20 - 30 . doi: 10.11975/j.issn.1002-6819.2019.24.003 [3] 韩绿化.蔬菜穴盘苗钵体力学分析与移栽机器人设计研究[D].镇江:江苏大学,2014.HAN Lvhua.Mechanical analysis of the root lumps anddevelopment of a robotic transplanter for vegetable plug seedlings[D].Zhenjiang:Jiangsu University,2014. [4] 朱德泉,储婷婷,武立权,等.宽窄行配置对机插中晚稻生长特性及产量的影响[J].农业工程学报,2018,34(18): 102 - 112 . doi: 10.11975/j.issn.1002-6819.2018.18.013ZHU Dequan,CHU Tingting,WU Liquan,et al.Effects of spacing-adjustable wide-narrow row on growth characteristics and yield of machine-transplanted mid- and late- season rice[J].Transactions of the Chinese Society of Agricultural Engineering,2018,34(18): 102 - 112 . doi: 10.11975/j.issn.1002-6819.2018.18.013 [5] 陈训教,吕志军,薛向磊,等.无线遥控步行插秧机的设计与试验[J].农业工程学报,2017,33(17): 10 - 17 . doi: 10.11975/j.issn.1002-6819.2017.17.002CHEN Xunjiao,LV Zhijun,XUE Xianglei,et al.Design and performance experiment of wireless remote control walking rice transplanter[J].Transactions of the Chinese Society of Agricultural Engineering,2017,33(17): 10 - 17 . doi: 10.11975/j.issn.1002-6819.2017.17.002 [6] 陈海涛,赵阳,侯守印,等.同步膜上开孔插秧装置运动学仿真与参数优化试验[J].农业工程学报,2016,32(11): 25 - 30 . doi: 10.11975/j.issn.1002-6819.2016.11.004CHEN Haitao,ZHAO Yang,HOU Shouyin,et al.Kinematics simulation and parameter optimization experiment for transplanting synchronous puncher[J].Transactions of the Chinese Society of Agricultural Engineering,2016,32(11): 25 - 30 . doi: 10.11975/j.issn.1002-6819.2016.11.004 [7] 吕伟生,曾勇军,石庆华,等.基于机插晚稻分蘖成穗特性获取基本苗定量参数[J].农业工程学报,2016,32(1): 30 - 37 . doi: 10.11975/j.issn.1002-6819.2016.01.004LV Weisheng,ZENG Yongjun,SHI Qinghua,et al.Calculation of quantitative parameters of basic population of machine transplanted late rice based on its tillering and panicle formation characteristics[J].Transactions of the Chinese Society of Agricultural Engineering,2016,32(1): 30 - 37 . doi: 10.11975/j.issn.1002-6819.2016.01.004 [8] 朱德泉,熊玮,蒋锐,等.2ZGK-6型可调宽窄行高速水稻插秧机设计与试验[J].农业工程学报,2016,32(21): 37 - 45 . doi: 10.11975/j.issn.1002-6819.2016.21.005ZHU Dequan,XIONG Wei,JIANG Rui,et al.Design and experiment of 2ZGK-6 type spacing-adjustable wide-narrow row high speed rice transplanter[J].Transactions of the Chinese Society of Agricultural Engineering,2016,32(21): 37 - 45 . doi: 10.11975/j.issn.1002-6819.2016.21.005 [9] 孙良,祝建彬,陈建能,等.基于球面曲线的空间非匀速行星轮系分插机构逆向设计[J].农业工程学报,2014,30(7): 9 - 17 . doi: 10.3969/j.issn.1002-6819.2014.07.002SUN Liang,ZHU Jianbin,CHEN Jianneng,et al.Reverse design of transplanting mechanism with spatial planetary gear train based on spherical curve[J].Transactions of the Chinese Society of Agricultural Engineering,2014,30(7): 9 - 17 . doi: 10.3969/j.issn.1002-6819.2014.07.002 [10] 李革,应孔月,郑峰君,等.基于无函数表达节曲线的非圆齿轮分插机构设计与试验[J].农业工程学报,2014,30(23): 10 - 16 . doi: 10.3969/j.issn.1002-6819.2014.23.002LI Ge,YING Kongyue,ZHENG Fengjun,et al.Design and experiment of noncircular gears transplanting mechanism based on pitch curve with nonfunction expression[J].Transactions of the Chinese Society of Agricultural Engineering,2014,30(23): 10 - 16 . doi: 10.3969/j.issn.1002-6819.2014.23.002 [11] 祝建彬,孙良,刘晓龙,等.斜齿交错−非圆锥齿轮行星系水稻宽窄行分插机构设计与优化[J].农业工程学报,2014,30(11): 21 - 29 . doi: 10.3969/j.issn.1002-6819.2014.11.003ZHU Jianbin,SUN Liang,LIU Xiaolong,et al.Design and optimization of transplanting mechanism with planetary gear train composed of helical gears and noncircular bevel gears[J].Transactions of the Chinese Society of Agricultural Engineering,2014,30(11): 21 - 29 . doi: 10.3969/j.issn.1002-6819.2014.11.003 [12] 韩绿化,毛罕平,赵慧敏,等.蔬菜穴盘育苗底部气吹式钵体松脱装置设计[J].农业工程学报,2019,35(4): 37 - 45 . doi: 10.11975/j.issn.1002-6819.2019.04.005HAN Lvhua,MAO Hanping,ZHAO Huimin,et al.Design of root lump loosening mechanism using air jets to eject vegetable plug seedlings[J].Transactions of the Chinese Society of Agricultural Engineering,2019,35(4): 37 - 45 . doi: 10.11975/j.issn.1002-6819.2019.04.005 [13] 刘洋,毛罕平,韩绿化,等.基于Micro-CT的黄瓜苗坨夹取破损检测及取苗参数优化[J].农业工程学报,2018,34(12): 27 - 34 . doi: 10.11975/j.issn.1002-6819.2018.12.004LIU Yang,MAO Hanping,HAN Lvhua,et al.Plug damage detection and parameter optimization of picking up cucumber seedlings from tray cells based on Micro-CT[J].Transactions of the Chinese Society of Agricultural Engineering,2018,34(12): 27 - 34 . doi: 10.11975/j.issn.1002-6819.2018.12.004 [14] 韩绿化,毛罕平,胡建平,等.蔬菜穴盘苗自动精确移栽组合式取苗机构设计与测试[J].农业工程学报,2015,31(S2): 17 - 23 . doi: 10.11975/j.issn.1002-6819.2015.z2.003HAN Lvhua,MAO Hanping,HU Jianping,et al.Design and test of combined pick-up device for automatic and precise transplanting of vegetable plug seedlings[J].Transactions of the Chinese Society of Agricultural Engineering,2015,31(S2): 17 - 23 . doi: 10.11975/j.issn.1002-6819.2015.z2.003 [15] 马瑞峻,萧金庆,郑普峰,等.穴盘水稻秧苗茎秆蠕变与应力松弛特性的试验研究[J].农业工程学报,2018,34(13): 43 - 53 . doi: 10.11975/j.issn.1002-6819.2018.13.006MA Ruijun,XIAO Jinqing,ZHENG Pufeng,et al.Experimental study on characteristics of creep and stress relaxation for rice seedling stem raised in cell tray[J].Transactions of the Chinese Society of Agricultural Engineering,2018,34(13): 43 - 53 . doi: 10.11975/j.issn.1002-6819.2018.13.006 [16] 宋建农,王苹,魏文军,等.水稻秧苗抗拉力学特性及穴盘拔秧性能的力学试验研究[J].农业工程学报,2003,19(6): 10 - 13 . doi: 10.3321/j.issn:1002-6819.2003.06.003SONG Jiannong,WANG Ping,WEI Wenjun,et al.Experimental research on tensile strength of rice seedlings and force of pulling out seedlings from trays[J].Transactions of the Chinese Society of Agricultural Engineering,2003,19(6): 10 - 13 . doi: 10.3321/j.issn:1002-6819.2003.06.003 [17] 郑旭,张宗俭,段韫丹,等.湿润剂对基质水分吸持和白菜穴盘苗生长的影响[J].农业工程学报,2023,39(1): 188 - 194 . doi: 10.11975/j.issn.1002-6819.202210043ZHENG Xu,ZHANG Zongjian,DUAN Yundan,et al.Effects of wetting agent application on substrate water absorption and Chinese cabbage plug seedlings[J].Transactions of the Chinese Society of Agricultural Engineering,2023,39(1): 188 - 194 . doi: 10.11975/j.issn.1002-6819.202210043 [18] 高国华,冯天翔,李福.斜入式穴盘苗移栽手爪工作参数优化及试验验证[J].农业工程学报,2015,31(24): 16 - 22 . doi: 10.11975/j.issn.1002-6819.2015.24.003GAO Guohua,FENG Tianxiang,LI Fu.Working parameters optimization and experimental verification of inclined-inserting transplanting manipulator for plug seedling[J].Transactions of the Chinese Society of Agricultural Engineering,2015,31(24): 16 - 22 . doi: 10.11975/j.issn.1002-6819.2015.24.003 [19] 廖庆喜,胡先朋,张照,等.油菜移栽机分苗装置分苗过程与钵苗钵体完整性分析[J].农业工程学报,2015,31(16): 22 - 29 . doi: 10.11975/j.issn.1002-6819.2015.16.004LIAO Qingxi,HU Xianpeng,ZHANG Zhao,et al.Analysis on detaching process of detaching device and seedling pot integrity about rape transplanter[J].Transactions of the Chinese Society of Agricultural Engineering,2015,31(16): 22 - 29 . doi: 10.11975/j.issn.1002-6819.2015.16.004 [20] 童俊华,蒋焕煜,蒋卓华,等.钵苗自动移栽机器人抓取指针夹持苗坨参数优化试验[J].农业工程学报,2014,30(16): 8 - 16 . doi: 10.3969/j.issn.1002-6819.2014.16.002TONG Junhua,JIANG Huanyu,JIANG Zhuohua,et al.Experiment on parameter optimization of gripper needles clamping seedling plug for automatic transplanter[J].Transactions of the Chinese Society of Agricultural Engineering,2014,30(16): 8 - 16 . doi: 10.3969/j.issn.1002-6819.2014.16.002 [21] TING K C,GIACOMELLI G A,SHEN S J,et al.Robot workcell for transplanting of seedlings.Part II.end-effector development[J].Transactions of the ASAE,1990,33(3). [22] 陈林涛,马旭,李泽华,等.水稻秧盘形变测度方法与等级评价研究[J].农业机械学报,2018,49(6): 159 - 166 . doi: 10.6041/j.issn.1000-1298.2018.06.018CHEN Lintao,MA Xu,LI Zehua,et al.Deformation measurement technology and grade evaluation of rice seedling trays[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(6): 159 - 166 . doi: 10.6041/j.issn.1000-1298.2018.06.018 -

下载:

下载:

京公网安备 11010502037498号

京公网安备 11010502037498号