Development of Straw Pyrolysis Equipment Based on Biochar Syngas Coupling Reforming

-

摘要:

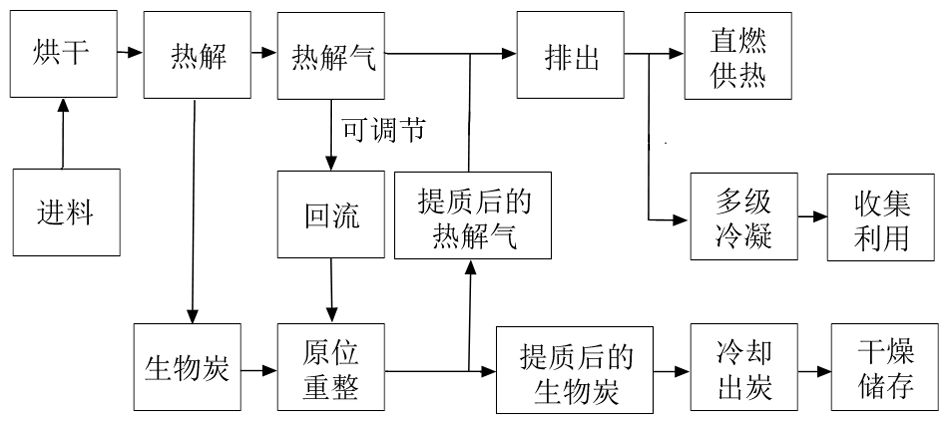

针对当前生物质热解炭化设备存在产物质量较差、能量损耗严重等问题,采用多级布风搅拌和气体回流重整等方法,提出生物质炭气原位耦合重整工艺路线,并对炉体、压实机构和多级布风搅拌出料机构进行设计,研发立式移动床生物质炭化设备。以花生壳为原料开展热解炭化试验,结果表明,原料处理能力1312 kg/h,生物炭得率27.8%,热解气热值6.3 MJ/m3,焦油转化率71.3%,各项性能指标均达到设计要求。

Abstract:In view of poor product quality and serious energy loss of current biomass pyrolysis equipment, methods such as multi-stage air distribution and gas reflux reforming were used to propose a process route for biochar syngas coupling reforming.Furnace body, compaction mechanism and multi-stage air distributing stirring and discharging mechanism were designed, and vertical moving bed biomass pyrolysis equipment was developed.Pyrolysis test was carried out with peanut shells as raw materials.Results showed that raw material processing capacity was 1312 kg/h, biochar yield was 27.8%, calorific value of pyrolysis gas was 6.3 MJ/m3, tar conversion rate was 71.3%, and all performance indicators reached design requirements.

-

Keywords:

- biomass /

- straw /

- pyrolysis /

- internal heating /

- biochar syngas coupling /

- reforming

-

表 1 立式移动床热解反应器主要技术参数

Table 1. Main technical parameters of vertical moving bed pyrolysis reactor

指标 参数 炉体高度/mm 3 500 炉体直径/mm 1 200 配套动力/kW 21.3 加热方式 内加热 设计原料处理能力/(kg·h−1) 1 300 出炭口数量 4 布风方式 环状多级布风 表 2 试验结果

Table 2. Test result

测试指标 测得值 原料处理量/(kg·h−1) 1312 生物炭得率/% 27.8 出炭温度/°C 462 热解气热值/(MJ·m−3) 6.3 焦油转化率/% 71.3 -

[1] 夏璐,赵蕊,金海燕,等.生物炭对土壤理化性质及玉米生长影响的研究进展[J].天津农学院学报,2018,25(2):64- 69. doi: 10.19640/j.cnki.jtau.2018.02.016XIA Lu,ZHAO Rui,JIN Haiyan,et al.Research progress of the effects of biochar on physicochemical properties of soil and growth of maize[J].Journal of Tianjin Agricultural University,2018,25(2):64-69. doi: 10.19640/j.cnki.jtau.2018.02.016 [2] 马献发,李伟彤,孟庆峰,等.生物炭对土壤重金属形态特征及迁移转化影响研究进展[J].东北农业大学学报,2017,48(6):82-90. doi: 10.3969/j.issn.1005-9369.2017.06.011MA Xianfa,LI Weitong,MENG Qingfeng,et al.Research advance on biochars of the speciation,mobility and transfer of heavy metals in soils[J].Journal of Northeast Agricultural University,2017,48(6):82-90. doi: 10.3969/j.issn.1005-9369.2017.06.011 [3] 刘悦,黎子涵,邹博,等.生物炭影响作物生长及其与化肥混施的增效机制研究进展[J].应用生态学报,2017,28(3): 1 030-1 038. doi: 10.13287/j.1001-9332.201703.035LIU Yue,LI Zihan,ZOU Bo,et al.Research progress in effects of biochar application on crop growth and synergistic mechanism of biochar with fertilizer[J].Chinese Journal of Applied Ecology,2017,28(3): 1 030- 1 038. doi: 10.13287/j.1001-9332.201703.035 [4] 陈温福,张伟明,孟军.农用生物炭研究进展与前景[J].中国农业科学,2013,46(16): 3 324- 3 333. doi: 10.3864/j.issn.0578-1752.2013.16.003CHEN Wenfu,ZHANG Weiming,MENG Jun.Advances and prospects in research of biochar utilization in agriculture[J].Scientia Agricultura Sinica,2013,46(16): 3 324- 3 333. doi: 10.3864/j.issn.0578-1752.2013.16.003 [5] WANG Nana, SI Hui, YI Weiming, et al.Design and operation of a mobile fast pyrolysis system utilizing a novel double pipe fluidized bed reactor[J].Fuel Processing Technology, 2021.DOI: 10.1016/J.FUPROC.2021.107005. [6] KONG Dali, LUO Kun, WANG Shuai, et al.Particle behaviours of biomass gasification in a bubbling fluidized bed[J].Chemical Engineering Journal, 2022.DOI: 10.1016/J.CEJ.2021.131847. [7] RAYMUNDO L M,ESPINDOLA J S,BORGES F C,et al.Continuous fast pyrolysis of rice husk in a fluidized bed reactor with high feed rates[J].Chemical Engineering Communications,2021,208(11):1 553- 1 563. doi: 10.1080/00986445.2020.1798937 [8] ZHANG Dongdong, HAN Peilin, YANG Rui, et al.Fuel properties and combustion behaviors of fast torrefied pinewood in a heavily loaded fixed-bed reactor by superheated steam[J].Bioresource Technology, 2021.DOI: 10.1016/J.BIORTECH.2021.125929. [9] 杨楠楠.生物质热解气化与低热值热解气燃烧工艺优化与实验研究[D].天津: 河北工业大学, 2017.YANG Nannan.Optimization and experiment of biomass pyrolysis gasfication and low calorific value pyrolysis gas combustion[D].Tianjin: Hebei University of Technology, 2017. [10] LI Ping,XU Ruiyang,WANG Nana,et al.Pneumatic feeding characteristics into dense-phase region of a fluidized bed for biomass pyrolysis[J].Powder Technology,2021,387:421-433. doi: 10.1016/j.powtec.2021.04.039 [11] 贾吉秀,赵立欣,孟海波,等.生物质热解焦油燃烧试验系统设计与试验[J].农业机械学报,2018,49(12):341-346.JIA Jixiu,ZHAO Lixin,MENG Haibo,et al.Design and experiment on biomass pyrolysis tar combustion system[J].Transactions of the Chinese Society for Agricultural Machinery,2018,49(12):341-346. [12] HOANG A T, ONG H C, FATTAH I M R, et al.Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability[J].Fuel Processing Technology, 2021.DOI: 10.1016/j.fuproc.2021.106997. [13] 丁赤民, 李建隆.秸秆快速热裂解产物的净化系统: CN101602953[P].2009-12-16. [14] 丁赤民, 李建隆.秸秆快速热裂解生产燃料的方法及其燃料产品: CN101602954 [P].2009-12-16. [15] 吴国鑫.下吸式移动床中生物质颗粒运动行为的研究[D].青岛: 青岛科技大学, 2017.WU Guoxin.The study of biomass particle movement behavior in the suction moving bed[D].Qingdao: Qingdao University of Science and Technology, 2017. [16] CHEN Guanyi, DONG Xiaoshan, YAN Beibei, et al.Photothermal steam reforming: a novel method for tar elimination in biomass gasification[J].Applied Energy, 2022.DOI: 10.1016/J.APENERGY.2021.117917. [17] DONG Li,XU Guangwen,SUDA T,et al.Potential approaches to improve gasification of high water content biomass rich in cellulose in dual fluidized bed[J].Fuel Processing Technology,2010,91(8):882-888. doi: 10.1016/j.fuproc.2009.12.012 [18] 王芳,曾玺,孙延林,等.两段流化床中半焦催化脱除焦油特性[J].化工学报,2017,68(10): 3 762- 3 769.WANG Fang,ZENG Xi,SUN Yanlin,et al.Characteristics of char catalytic reforming of tar in two-stage fluidized bed[J].CIESC Journal,2017,68(10): 3 762- 3 769. [19] 吴文广,罗永浩,陈祎,等.两段式固定床反应器中焦油脱除的实验研究[J].燃料化学学报,2012,40(2):177-183. doi: 10.3969/j.issn.0253-2409.2012.02.008WU Wenguang,LUO Yonghao,CHEN Yi,et al.Experimental study on tar destruction in a two stage fixed-bed reactor[J].Journal of Fuel Chemistry and Technology,2012,40(2):177-183. doi: 10.3969/j.issn.0253-2409.2012.02.008 [20] 陈冠益,颜蓓蓓,贾佳妮,等.生物质二级固定床催化热解制取富氢燃气[J].太阳能学报,2008,29(3):360-364. doi: 10.3321/j.issn:0254-0096.2008.03.020CHEN Guanyi,YAN Beibei,JIA Jiani,et al.Production of hydrogen-rich gas through pyrolysis of biomass in a two-stage reactor[J].Acta Energiae Solaris Sinica,2008,29(3):360-364. doi: 10.3321/j.issn:0254-0096.2008.03.020 [21] MOHSIN R, ABRAR I, ASHFAQ A, et al.Progress of the pyrolyzer reactors and advanced technologies for biomass pyrolysis processing[J].Sustainability, 2021.DOI: 10.3390/SU131911061. [22] 戴贡鑫.生物质热解机理及选择性调控研究[D].杭州: 浙江大学, 2020.DAI Gongxin.Fundamental research on biomass fast pyrolysis and selective conversion[D].Hangzhou: Zhejiang University, 2020. [23] 邓尚洵,解海卫,张艳,等.典型生物质热解特性实验研究[J].石油化工应用,2018,37(12):98-101. doi: 10.3969/j.issn.1673-5285.2018.12.021DENG Shangxun,XIE Haiwei,ZHANG Yan.Experimental study on pyrolysis characteristics of typical biomass[J].Petrochemical Industry Application,2018,37(12):98-101. doi: 10.3969/j.issn.1673-5285.2018.12.021 [24] 鲁敏,熊祖鸿,房科靖,等.生物质热解粗燃气催化重整特性和机理研究[J].太阳能学报,2020,41(10):332-339.LU Min,XIONG Zuhong,FANG Kejing,et al.Catalytic reforming characteristics and mechanism of raw gas from biomass pyrolysis[J].Acta Energiae Solaris Sinica,2020,41(10):332-339. [25] 丛宏斌,姚宗路,赵立欣,等.自燃连续式生物质热解炭气油联产系统燃气净化分离技术工艺研究[J].可再生能源,2015,33(9): 1 393- 1 397. doi: 10.13941/j.cnki.21-1469/tk.2015.09.019CONG Hongbin,YAO Zonglu,ZHAO Lixin,et al.Research on gas separation and purification technology for continuous pyrolysis system with biomass spontaneous combustion[J].Renewable Energy Resources,2015,33(9): 1 393- 1 397. doi: 10.13941/j.cnki.21-1469/tk.2015.09.019 [26] 贾吉秀.连续式生物质热解炭化设备的研制[D].泰安: 山东农业大学, 2017.JIA Jixiu.Study on continuous biomass pyrolysis equipment[D].Tai'an: Shandong Agricultural University, 2017. [27] 丛宏斌,赵立欣,姚宗路,等.内加热连续式生物质炭化设备的研制[J].太阳能学报,2014,35(8): 1 529- 1 535. doi: 10.3969/j.issn.0254-0096.2014.08.035CONG Hongbin,ZHAO Lixin,YAO Zonglu,et al.Development of internal heating continuous type biomass carbonization equipment[J].Acta Energiae Solaris Sinica,2014,35(8): 1 529- 1 535. doi: 10.3969/j.issn.0254-0096.2014.08.035 -

下载:

下载:

京公网安备 11010502037498号

京公网安备 11010502037498号